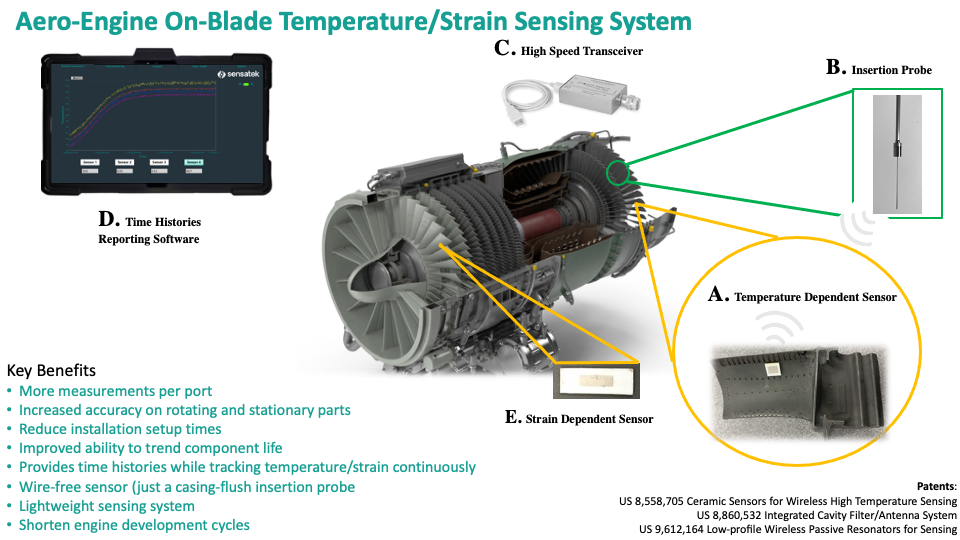

Air Force Awards $500,000 to Demo On-Blade Temp./Strain Sensors on GE Jet Engine.

Sensatek solidified 3 Memorandum of Understandings (MOUs) for prototype demonstration trials with three Air Force customers to increase engine time on wing by 20% from predicting more accurately maintenance cycles with on-blade Resonant Frequency sensors and eliminating 30% of engine life cycle time and costs from extending engine life. The solution features on-blade sensors applied as multi-functional thin film erosion-resistant coatings to enable continuous and real time measurement of temperature and strain in-situ on rotating turbine blades. This solution is positioned to reduce engine development life cycle time and costs by 200% from eliminating 30% of the time it takes to route and instrument cables, while eliminating 10 months in time in waiting on vendors to post process blade temperature data. Furthermore, in fielded systems, the solution could eliminate $1.1 billion in operational and sustainment costs across 2,823 Air Force weapon systems, with on-blade prediction capability in condition based maintenance enhanced (CBM+) programs.