Avoid multi-million dollar unexpected operations and maintenance costs with TurboTrack™

Improve gas turbine reliability by preventing common failures in blades and rotors with the insights from Sensatek’s blade assessment.

Whether your engines are facing strain during extreme weather conditions or operating in new ways they were not designed for as renewables have grown, you need trusted, high-quality data on your gas turbine blades operating conditions before your emissions and costs spiral out of control.

Our assessment provides you with:

How TurboTrack works

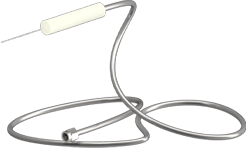

Unique high-temp wireless sensing system protected by multiple patents

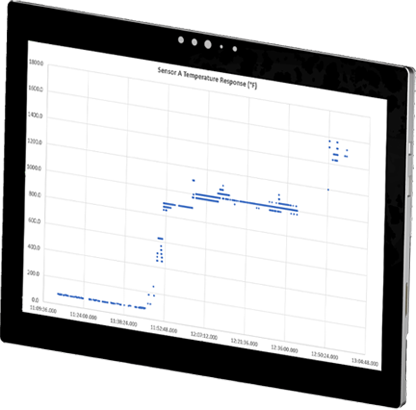

The TurboTrack blade assessment report includes comprehensive data, insights, and visuals to show you the realities of your engine operations that will act as a road map to potentially save you millions of dollars.

With extensive experience in propulsion technology, our driven team of experts will come to your location to apply the TurboTrack system on your engines and personally run all the tests.

We’re proud to fit our services to your unique needs, whether that be an emergency response within 48 hours after a turbine blade failure or scheduled monitoring during planned weeks-long maintenance.

Our blade assessment report is powered by TurboTrack—the first in situ temperature and strain monitoring system.

The TurboTrack system allows you to prioritize and schedule maintenance with precision based on the parts with the highest financial risk, thanks to real-time, repeatable trend data.

TurboTrack redefines sensor accuracy, hysteresis, and sensitivity as the most accurate and continuous monitoring technology applied directly to rotating parts.

Explore Our Groundbreaking Wireless On-Blade Sensor System

In this e-book you will learn more about:

Download our e-book

Our TurboTrack system alerted an OEM and utility to extremely high blade metal temperatures within a few hours of turbine operation, resulting in a timely remedy across a fleet of 25 engines at 10 power sites.

Our team found the temperature irregularity by: