Client: Sensatek Propulsion Technology, Inc.

Program: U.S. Air Force / AFWERX SBIR

Application: Wireless Passive Temperature Sensors for Helicopter Turbine Blades

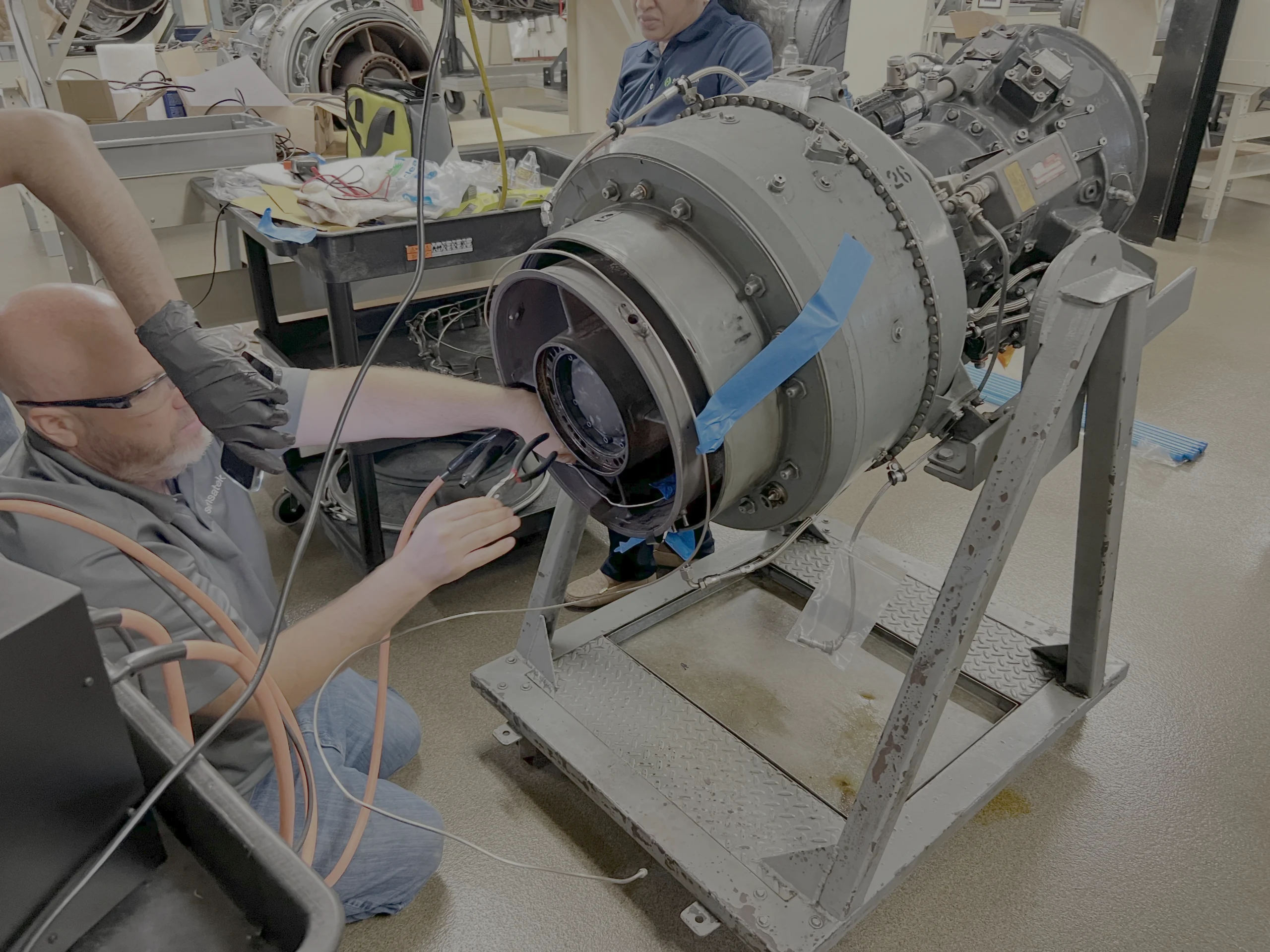

Use Case: T53 Turboshaft Engine Testing and Commercial Engine Health Monitoring

Turbine blades in helicopters operate under extreme conditions—temperatures exceeding 850°C, rotation speeds over 16,000 RPM, and g-forces of 45,000g. Traditional wired sensors can’t withstand this environment and pose significant limitations in cost, data latency, and maintenance downtime.

The Air Force needed a non-intrusive, real-time, and survivable monitoring solution for turbine blade temperature and potential structural strain during engine operation.

Sensatek developed and successfully tested a wireless passive RF sensor system using polymer-derived ceramics (PDCs) and platinum metallization. The system comprises:

This system reads the temperature from rotating blades up to 1,070°C, withstanding high-speed rotation and vibration without requiring a slip ring or external cooling.

Developed, tested, and refined full sensing chain—sensor, antenna, signal conditioning, and software GUI.

System validated through multiple full-speed runs in a T53 test cell at Embry-Riddle Aeronautical University. All 14 Air Force-defined requirements (e.g., temperature accuracy, survivability, signal stability) were met or exceeded.

Tack-welding proved superior to brazing and flame-spraying, with sensors surviving over 1 hour of continuous high-temperature testing.

Performed CFD and FEA simulations to assess impact on airflow, heat transfer, and structural vibration—critical for certifying deployability on rotating engine components.

Sensors and software were customized for both defense (e.g., T53, J85 engines) and commercial aerospace/energy turbines (e.g., Siemens, GE, Rolls-Royce gas turbines).

Sensatek developed and successfully tested a wireless passive RF sensor system using polymer-derived ceramics (PDCs) and platinum metallization. The system comprises:

“Sensatek’s breakthrough in passive wireless temperature sensing for rotating engine parts gives the Air Force a mission-ready, high-temperature sensing solution. With full system integration and real-time analytics, this technology sets the stage for predictive maintenance and autonomous engine health monitoring.”

— AFWERX Program Evaluator